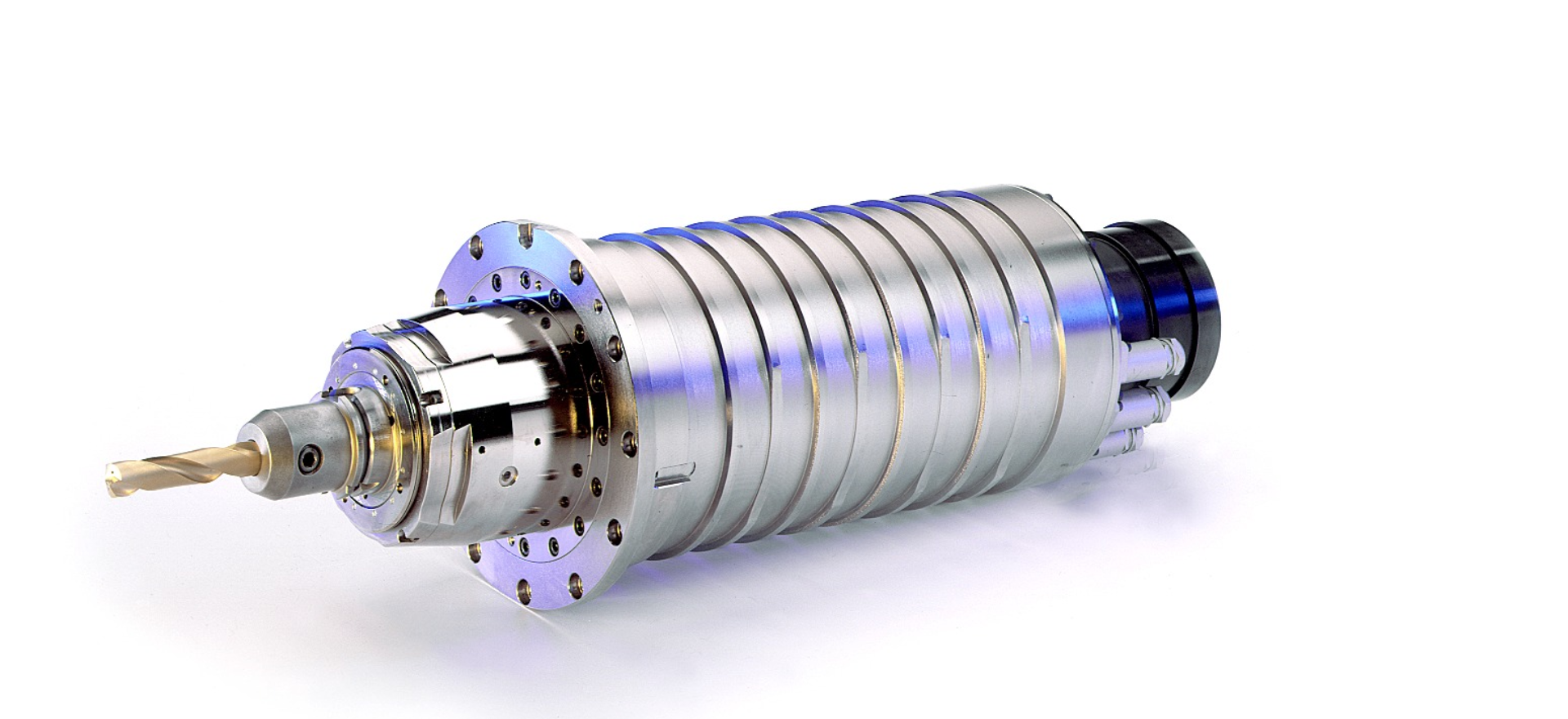

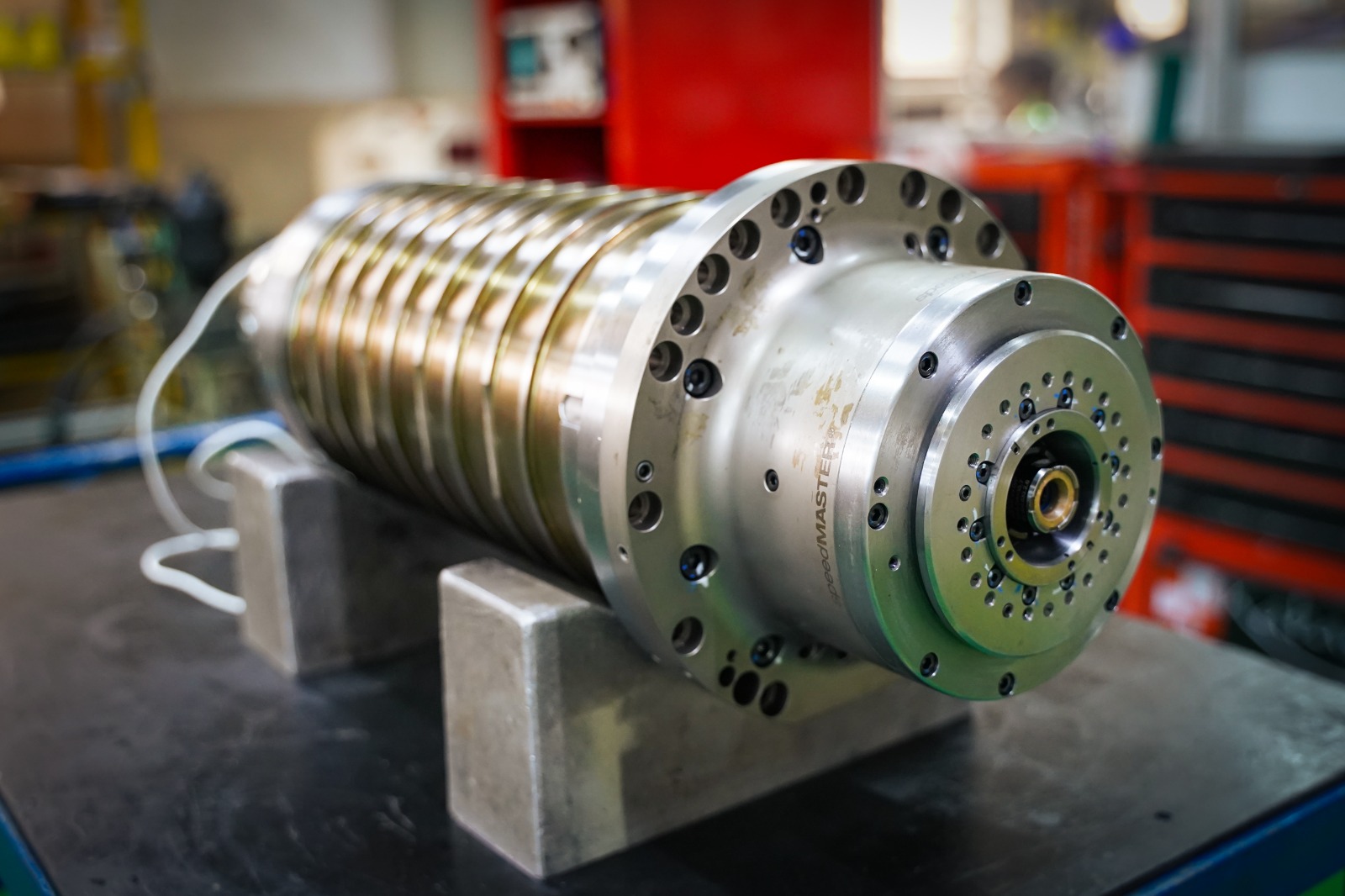

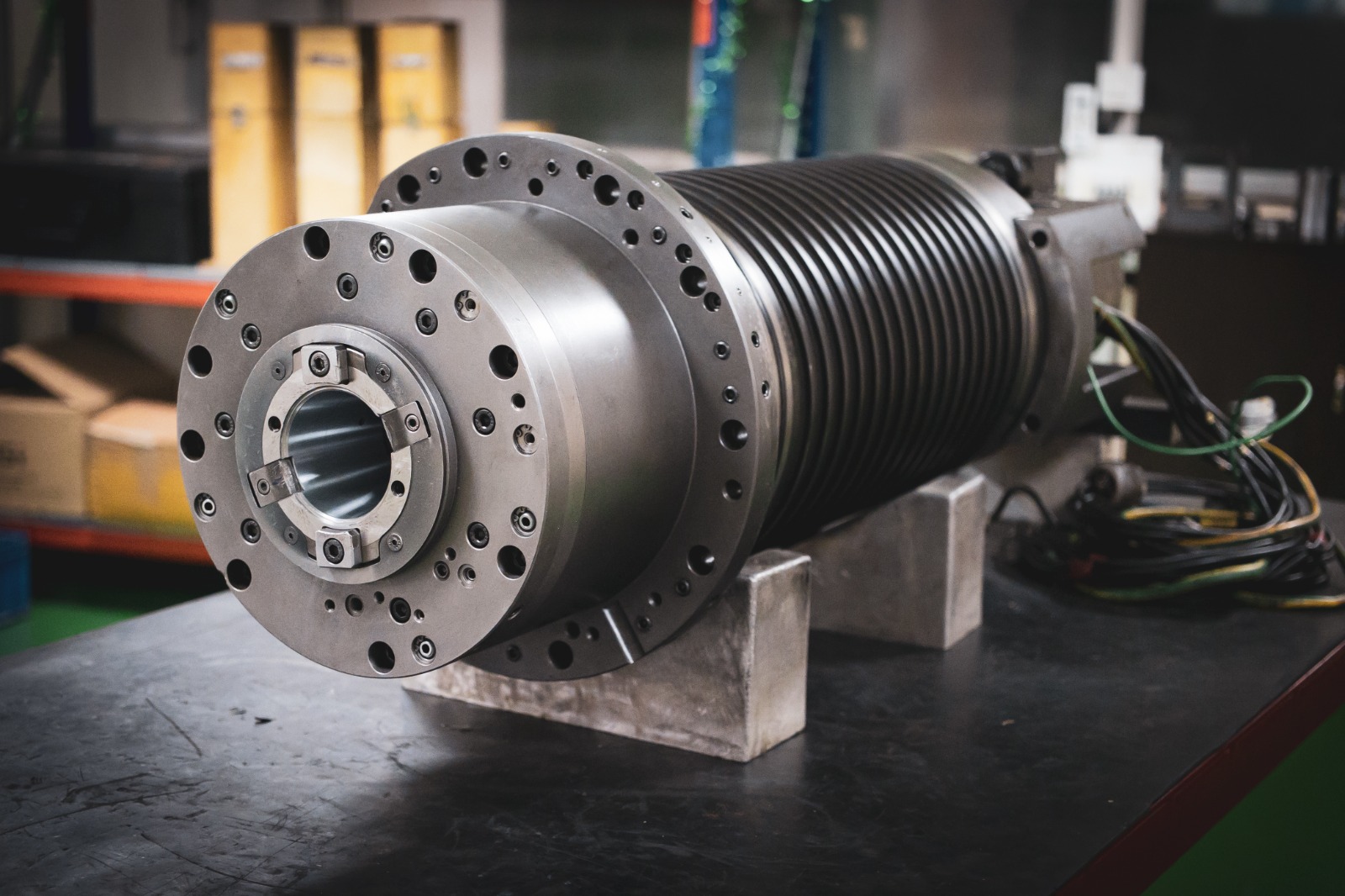

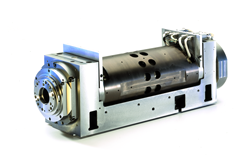

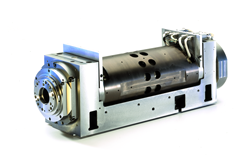

Service center for : KESSLER, GAMFIOR, FISHER, IBAG, GMN, HYUNDAI, HASS, etc.

Building Relationships That Last

Company Profile

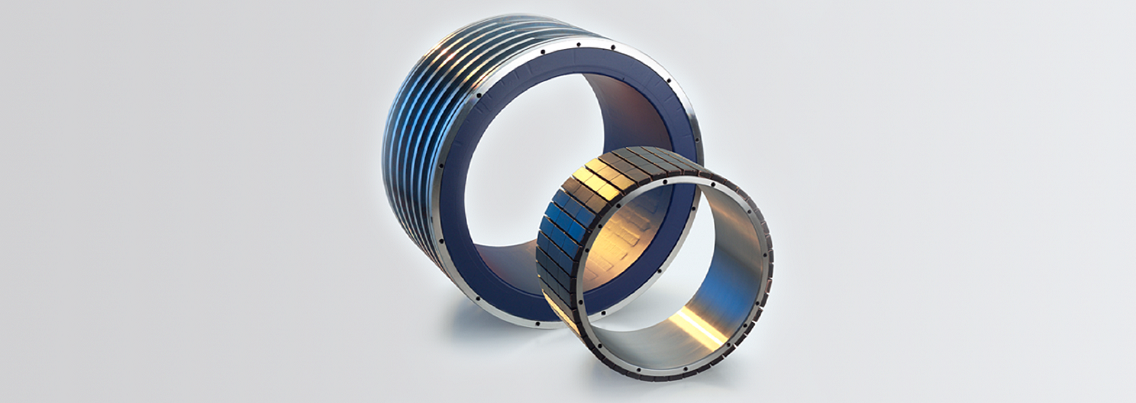

Established in the year 2006.Professionally managed.State of art technology and dedicated workshop of 2000sq.ft.Specialized in high precision spindle repairs.Applications-turning, milling, grinding etc.Highly experienced and OEM trained, fully equipped technical team.Quality workmanship by committed hands.Service tenure for OEM and End users.Clientele from INDIA and abroad.Authorized service partner for Franz Kessler GmbH – Germany.

R H Power Utilities Pvt Ltd